Title: IIoT and AI: The Synergistic Symphony Transforming Industrial Landscapes

Introduction: The Dawn of a New Industrial Revolution

The industrial world has always been a hub of innovation, constantly evolving with the advent of new technologies. Today, two groundbreaking forces—Industrial Internet of Things (IIoT) and Artificial Intelligence (AI)—are converging to redefine the way industries operate. This fusion is creating an era of smart factories, predictive maintenance, and enhanced efficiency like never before.

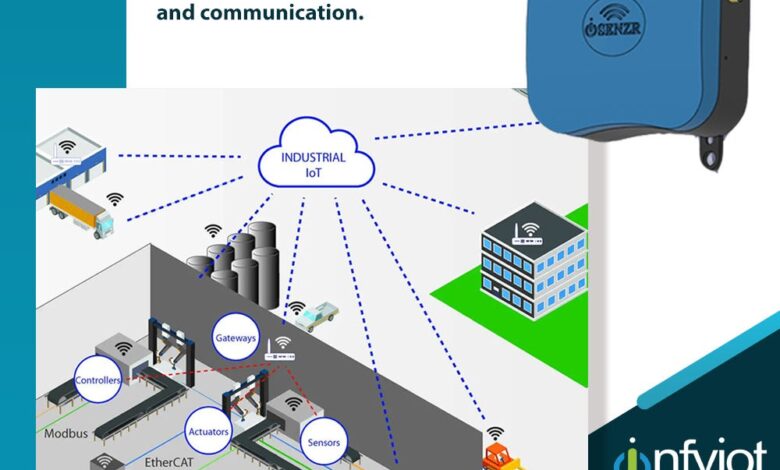

Industrial IoT refers to the network of interconnected sensors, machines, and devices that collect and transmit data across industrial environments. AI, on the other hand, empowers these systems to analyze data, recognize patterns, and make intelligent decisions without human intervention. Together, they form a synergistic relationship that is revolutionizing industries worldwide.

This article delves into the powerful combination of IIoT and AI, exploring their impact on various industrial sectors, the benefits they bring, and the challenges they pose.

The Marriage of IIoT and AI: A Game-Changer for Industries

The integration of IIoT and AI is not just a fleeting trend but a fundamental shift in industrial operations. IIoT enables the collection of real-time data from machinery, sensors, and industrial equipment, while AI provides the cognitive capabilities to process and act upon this data intelligently.

One of the most significant advantages of this merger is predictive maintenance. Traditional maintenance methods often rely on scheduled inspections, leading to unnecessary downtime or unexpected failures. With AI analyzing IIoT-collected data, machines can predict failures before they occur, ensuring timely interventions and reducing operational disruptions.

Furthermore, AI-driven analytics enhance supply chain management by predicting demand fluctuations, optimizing inventory levels, and improving logistics. In manufacturing, AI algorithms analyze IIoT data to detect quality deviations in production lines, reducing waste and improving product quality. This union of IIoT and AI is transforming industrial landscapes into intelligent, self-optimizing ecosystems.

Smart Factories: The Rise of Autonomous Production Facilities

Smart factories represent the pinnacle of IIoT and AI integration, where automation, real-time data processing, and machine learning algorithms work in harmony. These factories rely on interconnected devices to streamline operations, boost efficiency, and improve overall productivity.

For instance, AI-powered robots in assembly lines continuously adapt to changes in production demands, reducing errors and enhancing precision. Additionally, AI-driven predictive analytics enable manufacturers to adjust production schedules based on market trends, preventing overproduction or stock shortages.

Moreover, IIoT-enabled digital twins—virtual replicas of physical assets—allow manufacturers to simulate operations and test different scenarios before implementing changes in the real world. This not only reduces risks but also enhances decision-making processes, making industrial operations more agile and efficient.

Enhancing Worker Safety and Operational Efficiency

The industrial environment can be hazardous, with risks ranging from equipment malfunctions to exposure to harmful substances. The integration of IIoT and AI is significantly improving worker safety by providing real-time monitoring and automated responses to potential threats.

For example, AI-driven IIoT systems in construction sites or manufacturing plants can detect abnormal temperature spikes in machinery, signaling potential overheating issues. Wearable IIoT devices can monitor workers’ vital signs and alert supervisors if a worker is experiencing fatigue or health issues, preventing accidents before they happen.

In addition to safety enhancements, AI optimizes energy consumption by analyzing IIoT data from power grids, HVAC systems, and industrial equipment. By identifying inefficiencies, AI can recommend adjustments that reduce energy waste, lower costs, and contribute to sustainability efforts. This efficiency translates into significant cost savings and a reduced environmental footprint.

Challenges and Considerations in Implementing IIoT and AI

Despite the remarkable benefits of integrating IIoT and AI, industries must navigate several challenges to ensure seamless adoption. One of the primary concerns is cybersecurity. With an increasing number of connected devices, industrial systems become vulnerable to cyberattacks, data breaches, and system infiltrations.

Additionally, the implementation of AI-driven IIoT solutions requires substantial investment in infrastructure, including edge computing, cloud platforms, and data storage capabilities. Small and medium enterprises (SMEs) may find it challenging to allocate resources for these technologies, necessitating scalable and cost-effective solutions.

Another key consideration is workforce adaptation. While automation and AI improve efficiency, they also alter job roles, requiring employees to acquire new skills in data analysis, AI model management, and IIoT integration. Upskilling the workforce is essential to ensure a smooth transition into AI-powered industrial ecosystems.

The Future of IIoT and AI: What Lies Ahead?

The journey of IIoT and AI integration is still in its early stages, but the future holds immense promise. With advancements in 5G connectivity, edge computing, and deep learning algorithms, industrial operations will become even more autonomous, intelligent, and interconnected.

One exciting development is the rise of AI-powered edge devices that process IIoT data locally rather than relying on centralized cloud systems. This reduces latency, enhances real-time decision-making, and minimizes data transmission costs. Moreover, as AI models become more sophisticated, they will enable industries to achieve unprecedented levels of efficiency, sustainability, and innovation.

Governments and regulatory bodies are also stepping in to establish guidelines for ethical AI and IIoT implementation, ensuring responsible data usage and security measures. As industries continue to embrace these technologies, the synergy between IIoT and AI will unlock new possibilities that redefine the way we manufacture, distribute, and consume goods.

Conclusion: Embracing the Future of Industrial Intelligence

The integration of IIoT and AI is not just a technological advancement; it is a transformational force reshaping industrial landscapes across the globe. From predictive maintenance and smart factories to enhanced safety and operational efficiency, this powerful duo is setting new benchmarks for industrial excellence.

While challenges exist, the rewards far outweigh the obstacles. Industries that embrace IIoT and AI today will be at the forefront of innovation, equipped with the tools to drive efficiency, reduce costs, and create sustainable solutions for the future.

As we move forward, one thing is clear—IIoT and AI are no longer optional add-ons but essential components of a smarter, more connected industrial world. The future is here, and it is driven by the symphony of IIoT and AI working in perfect harmony.